When designing a new power supply for use in a specific application, one of the first things to consider will be appropriate thermal management. There are many types of cooling for power supplies, but this article will focus on the differences between heat sinks and cold plates.

Heat sinks and cold plates are close relatives when it comes to thermal management.* Both offer a conductive form of cooling — that is, cooling by direct contact between two components of different temperatures.

The primary difference between heat sinks and cold plates is the addition or lack of fins. Heatsinks have fins of varying sizes protruding from a metal plate. Cold plates are finless and made of a thicker metal plate.

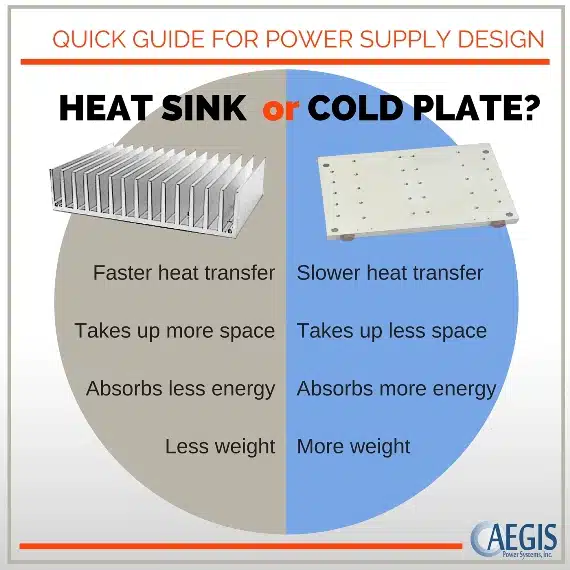

Both styles are suitable for application in a broad array of ac-dc or dc-dc power supplies. Heat sinks with fins allow for a quicker dissipation of heat due to increased surface contact with air. Alternatively, cold plates have a slower heat dissipation, but absorb more energy.

Space and weight restrictions will also guide selections between using a heat sink or cold plate. Although heat sinks are more effective at quickly dissipating heat, they do require more space than a cold plate. However, if weight is more of a concern, then keep in mind that heat sinks weigh less than a cold plate counterpart.

Use the simple chart above to quickly identify the differences between heat sinks and cold plates.

Selecting the appropriate cooling method is essential for designing a reliable and efficient power supply. For a simple guide on other types of thermal management for power supplies, please read our “Overview of Cooling Techniques for AC-DC and DC-DC Power Supplies.”

Need an efficient power supply for your specialized industrial, defense, electric vehicle, aircraft, or rack mount application? Contact us today for a free quote on custom power supplies.

*Heat sinks and cold plates are technically both a form of heat sink. However, in colloquial engineering jargon, “heat sinks” are those with fins while “cold plates” do not have fins.